Syringes

All SGE syringes are rated to 100 psi unless otherwise stated.

To calculate pumping speed when using a syringe pump, please refer to the details below:

If the tubing is flexible and has an ID similar to the OD of the needle (you may be able to change needles to achieve this), then the simplest thing to try is pushing the tubing over the needle. Be very careful if it is a bevel tip needle as it may slice through the wall of the tubing. A cone tip or dome tip needle will make it easier.

If the tubing doesn't have the right ID, or if it isn't flexible enough, Luer Lock syringe (or one with a 1/4-28 UNF male thread) can be used along with a Luer Lock (or screw thread) adaptor.

If the gas being sampled is under pressure then you definitely would want to use a syringe with a valve, otherwise some of the sample will escape.

It is also a good idea to use a syringe with a valve if the sample, once taken, is not going to be immediately introduced into the GC.

Other possible reasons for using a valve are, very low level samples, very concentrated samples, toxic, corrosive or malodorous samples, or if you need to pressurize sample prior to injection.

- Fixed needle, fixed Luer Lock, and 500 nL - 5 μL NanoVolume syringes can be heated in an oven to 70°C

- Removable and fixed needle 5 - 500 μL all metal plunger syringes can be heated in an oven to 100°C

- Removable needle and removable Luer 1 mL - 100 mL PTFE tipped plunger and dispenser syringes can be heated in an oven to 100°C

Note: Plungers should be removed before heating. Ensure heating and cooling is a gradual process to prevent the glass barrel from breaking

Syringes can be autoclaved but we would recommend the following procedure:

Autoclaving will usually heat a syringe to about 121°C so that is too high and usually the cool down is speeded up by purging the system too early and that results in the syringe breaking. However it is generally possible to reduce the autoclave temperature to 100°C, extend the time, and there is usually a setting to allow for a slower cool down.

Note: Plungers should be removed before autoclaving.

Some solvents will gradually dissolve the glue used to hold the back flange and the front flange (fixed needle or removable needle thread). It's a matter of limiting the syringe's exposure to the solvent (both the length of time and the area exposed).

Do not immerse front flange below the level of the solvent. After use rinse syringe with clean solvent, followed by acetone. Then disassemble the syringe and allow it to dry.

- 5-10 μL syringes - 10-32 UNF (not 5 μL NanoVolume)

- 25 μL to 2.5 mL - 1/4-28 UNF

- 5 mL to 2 L - 7/16-28 UNEF

Needle length refers to the exposed length of the needle when fitted to syringe. Choose a replacement needle by selecting the syringe volume, needle length, OD and tip style.

For example, a 10 µL MicroVolume syringe part number 002050) is supplied with a 50 mm bevel tip needle (part number 037110). This can be replaced with the same needle, or any needle designed for 10 µL syringes.

Jumbo syringes

The acrylic barrel will handle 30 psi. However to achieve this would require a force on the plunger of over 500 pounds.

Dimensions:

- 500 mL 0.22 x 2.283" OD (part number 032527)

- 1000 mL 0.22 x 3.52" OD (part number 032532)

- 2000 mL 0.22 x 4.646" OD (part number 032537)

eVol

Please refer to product specifications in:

trajanscimed.com

If you change from dispensing one type of liquid (e.g. water) to another type of liquid (e.g. ethanol) then to get the best possible results, we would suggest re-calibrating to take into account factors such as differences in viscosity.

Apart from this, how often the calibration needs to be done will probably be determined by whatever quality system (in-house or external accreditation) the user is operating under. For example how often do they calibrate any other pipetting devices?

eVol is designed that the user can easily calibrate it themselves using an appropriately accurate balance (in this case we would recommend that the balance would need a minimum resolution of ±0.0001 g).

However it may be that the users quality system requires that the calibration be done by appropriately accredited third party. Any company that offers a pipette calibration service should also be able to calibrate an eVol.

With the MEPS BINs we recommend that the flow rate during aspiration be limited to 15 μL/sec to prevent cavitation. This will increase analyte/sorbent contact time and extraction efficiency.

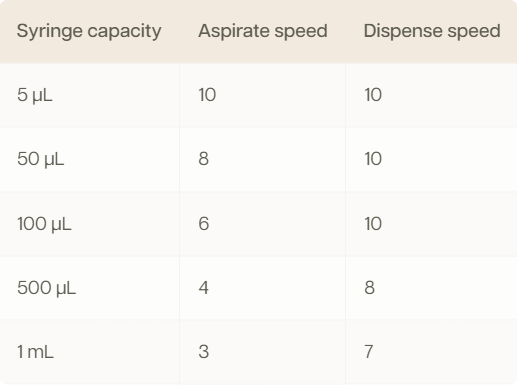

The eVol is supplied pre-loaded with default aspirate and dispense speeds for each syringe available; these have been set by experimentation with water. The default speeds per syringe are shown in the list below.

Each different liquid type has different ideal speed settings, dependent on liquid viscosity and needle bore diameter. The best way to determine the correct speed setting is by experimentation.

If the speed is too high on aspiration the liquid will cavitate or the coupling between the syringe plunger and the eVol will disconnect. Cavitation occurs when the pressure is reduced below the vapor pressure of the liquid, essentially the liquid boils. The reduction in pressure is due to the restriction in the needle working against the viscosity of the liquid. The vapor bubbles over time disappear but some aeration of the liquid will always remain. For very accurate dispensing it is vital that cavitation of any sort be avoided. Should the coupling between the syringe plunger and the eVol disconnect you will notice the plunger will stop earlier than expected, this sample should be discarded, the speed should be reduced and then retried.

Setting the speed too low on aspiration has no negative effect on the dispense other than increasing the time between separate dispenses. It is better to run a little to slow than risk running too fast and influencing the results.

If the speed is set too high on dispense the restriction in the needle, in combination with the viscosity of the liquid, cause’s significant back pressure to build up. This back pressure may overcome the available driving force of the eVol and the motor may stall. The stalling of the eVol does not damage the drive. The eVol can be re-zeroed at anytime should this happen by simply going into the Toolbox/Re-Zero menu and pressing the RUN button.

Setting the speed too low on dispense has no negative effect on the dispense other than increasing the time between separate dispenses. It is better to run a little to slow than risk running to fast and stalling the eVol drive mechanism.

You may also refer to the Support Tool - eVol aspirate/dispense speed calculator.

Lithium ion batteries work best if they are kept charged. Unlike Nickel cadmium batteries, they do not experience memory issues if they are not fully discharged before recharging. Like all batteries Lithium ion batteries do have a limited life. The battery in your eVol has an expected life of approximately 12 months. After this 12 month period you may notice that your eVol does not hold charge as it used to and needs to be charged more frequently.

The battery will eventually get to the state where it can no longer hold charge and needs to be replaced. Replacement batteries are available from your local distributor or Trajan office, and the replacement procedure is quite simple and straight forward.

To replace the battery simply unscrew the stainless steel screw on the back of the handle and remove the rear housing. Unplug the battery connector and remove the battery from its seat. Locate the new battery in the seat and secure, then reconnect the battery. Replace the rear housing and screw; be sure to not overtighten the screw as it can crack the plastic housing. It is recommended that after replacing the battery you give the new battery a full charge for 3-4 hours.

Organic solvents commonly have a low vapour pressure. This can lead to bubbles being drawn from the solvent if it is aspirated too quickly - cavitation.

The following short procedure (<60 seconds) has been successfully used to reduce cavitation by preparing eVol syringes for use with solvents with a low vapour pressure such as ether diethyl, petroleum ether, dichloromethane, heptane, hexane, ethanol, isopropanol, cyclohexane, chloroform, etc.

- Aspirate 2 syringe volumes with water.

- Aspirate 2 syringe volumes with alcohol (ethanol).

- Aspirate 1 syringe volume with chosen solvent (e.g. Hexane).

- Aspirate with chosen solvent (e.g. Hexane) as required.

Insufficient cleaning of the syringe may cause the plunger to swell. Manually aspirate the syringe with deionized water until the plunger movement feels smooth again.

Always ensure the eVol syringe is thoroughly cleaned after use.

Lithium ion batteries work best if they are kept charged. Unlike Nickel cadmium batteries, they do not experience memory issues if they are not fully discharged before recharging. Like all batteries Lithium ion batteries do have a limited life. The battery in your eVol has an expected life of approximately 12 months. After this 12 month period you may notice that your eVol does not hold charge as it used to and needs to be charged more frequently.

The battery will eventually get to the state where it can no longer hold charge and needs to be replaced. Replacement batteries are available from your local distributor or Trajan office, and the replacement procedure is quite simple and straightforward.

To replace the battery simply unscrew the stainless steel screw on the back of the handle and remove the rear housing. Unplug the battery connector and remove the battery from its seat. Locate the new battery in the seat and secure, then reconnect the battery. Replace the rear housing and screw; be sure to not overtighten the screw as it can crack the plastic housing. It is recommended that after replacing the battery you give the new battery a full charge for 3-4 hours.

The operation of the eVol touch-wheel is not affected when operated while wearing gloves.

The sensitivity of the touch-wheel and whether it makes a sound when scrolling can be selected through the toolbox menu as follows:

Setting/Menu/Options

Spinner sensitivity/Toolbox : Preferences : Spinner/Low/Medium/High

Spinner sounds/Toolbox : Preferences : Sounds : Spinner /On/Off

A fully charged battery allows for 2-4 hours of continuous dispensing use or approximately 3,500 dispensing cycles.

eVol can be run even with a depleted battery. If the battery is depleted the unit can be operated from an AC power supply by using the power supply supplied with the eVol kit. It will take approximately 30 seconds of charging to be.g.in running the motor.

Other needles can be used with the eVol syringes.

For the 5 μL eVol syringe there are a range of specific needles, please refer to the Part Number List - Replacement Needles (PDPN-1001-G).

For the 50 μL and 100 μL eVol syringes any 25-500 μL standard replacement needles can be used.

For the 500 μL and 1000 μL (1 mL) syringes any 1-2.5 mL standard replacement needles can be used.

Yes, the eVol can be used to aspirate and dispense viscous liquids. However the following must be considered:

- A needle with larger ID will help prevent restriction inside the needle.

- Lower aspirate and dispense speeds should be used.

Default speeds and pause settings can be saved in Syringe Methods that can be assigned to specific syringes or selected at any time. Up to ten (10) syringe methods can be created and stored with the following settings:

- Method ID

- Syringe volume suitable for this method

- Aspirate speed

- Aspirate pause

- Dispense speed

- Prime volume

- Prime Aspirate speed

- Prime Aspirate pause

- Prime Dispense speed

- Prime Dispense pause

- Prime cycles

Syringe Methods could be set up for different liquid viscosities and selected when required. For a high viscosity liquid the Syringe Method would be setup to use a slower aspirate and dispense speed and longer pauses.

MEPS

The MEPS BINs can be reused 40-100 times but this will depend on the matrix.

Each MEPS BIN contains 4 mg of phase.